Translate:

Metal Forming Specialties

Metal Spinning Solutions

The core of our services begins with the skills and expertise to spin metal into different concentric or round shapes. This process creates seamless metal components with a higher tensile strength. Best recommended for low production runs, art projects, and prototype designs for R&D.

Benefits of Metal Spinning

▪ Reduced costs at lower quantities ▪ Decreased lead time ▪ Flexibility in order quantity

▪ Low cost tooling spin mold ▪ Seamless metal parts, free of welds

Shapes Metal Spinning Can Produce

▪ cones (conical) ▪ bell shaped (parabolic) ▪ donuts (toroidal) ▪ half of a sphere (hemispheres) ▪ hourglass (venturi) ▪ cylinder ▪ lids

Spun Metal in Commercial Applications

▪ decorative metal parts ▪ architectural metal parts ▪ machinery parts ▪ cookware ▪ gas cylinders

▪ brass instruments ▪ motor housings ▪ solar energy products ▪ custom furniture

When selecting material for your spun part, it is important to consider the following: cost, shape of spinning, most important - the end application.

Metal Stamping Solutions

Supplementary to metal spinning, we have the capability to produce high volume productions through the metal stamping process. Metal stamping also allows for progressive dies, where multiple processes can be performed from less operations. Best recommended for square or complex (non-round) metal parts.

Benefits of Metal Stamping

▪ Most parts are low cost

▪ Commitment to high volume

▪ Multiple processes in one operation

Contact us to evaluate your project and see which process is

most cost effective for your application.

Custom Engineering & Consultation

With 40 years in the metal forming industry, we are well aware of all the perspectives required to produce an effective metal part. We created our machine shop to help bring ideas to life through manufacturing services like metal spinning, metal stamping, vacuum forming, spot welding & some machining.

Our Primary Goal

CUSTOMER SERVICE

your product + our services =

COMPETIVE PRICING & OUTSTANDING QUALITY

>> We are dedicated to excellence <<

Our belief in providing first-rate service in every aspect of our manufacturing business has allowed us to cooperate with customers in creating, lasting WIN-WIN relationships.

Metal Shop Services

Square Shearing

Square Shearing

Square Shearing

Straight cutting of flat, raw materials into strips, squares or rectangles

- up to 96" width -

Sheet Metal Rolling

Tool & Die Mold Building

Sheet Metal Rolling

Roll form flat, raw materials into tubes

- up to 48" width -

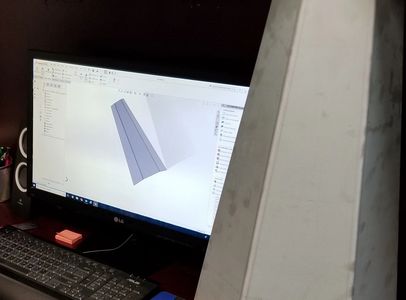

Metal Spinning in Action

Watch how master spinner & owner, Lou Estrada, forms a steel bellmouth housing for a fog misting system. Lou has been continuously developing his manufacturing skills for over 40 years. With his knowledge & expertise, we can manufacture different types of metal products, such as covers, bases, lids, caps, bowls, domes, dishes, rings, housing assemblies, etc.

Whatever the industry, we can help evaluate your project for the most cost effective manufacturing process.

Metal Manufacturing Services

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.